Feature

1. The machine is used for drilling holes, milling grooves, processing round holes and special-shaped holes, plane engraving of aluminum alloy profiles.

2. Adopted Taiwan Syntec CNC Control system.

3. Adopted the electric spindle, high precision, high safety and reliability.

4. X axle adopts high precision helical gear and rack, Y and Z axis adopt high-precision ball screw transmission, steady transmission and high precision.

5. By using programming software to transform and process G code automatically, easy operation, high efficiency and low labor intensity.

6. workbench can turn 180°,-90°0°+90°, it can realize material three-sides section processing by clamping one time, it can process deep and special-shaped holes through workbench turning, high efficiency and precision,

|

Parameter |

|

|

Air Pressure |

0.5~0.6MPa |

|

X/Y/Z Axis stroke |

3000mm*500mm*330mm |

|

Input Voltage |

380V 50Hz or As Customer need |

|

Input Power |

3KW China Air Cooling Spindle(6kw HSD Air Cooling Spindle for optional) |

|

Main axis rev |

18000rpm |

|

Handle type( Tool Clamp) |

ER25 for 3KW / ER32 for 6KW |

|

Suitable Milling Cutter Diameter |

ER 25: from 2mm to 16mm; ER 32: from 3mm to 20mm |

|

Processing range |

200*200 |

|

Overall size |

4180×1600×2250mm |

|

Weight |

1400kg |

|

Main accessory |

|

|

Control system |

|

|

Solenoid valve |

Airtec |

|

Cylinder |

Airtec |

|

Motor |

|

|

Air Filter Device |

Airtec |

|

Electrical Button and Switcher |

Schneider |

|

AC Contactor and Circuit Breaker |

Schneider |

|

Approach Switch |

|

|

Guide rail |

|

|

Standard accessory |

|

|

Cutters |

4pcs |

|

Air Gun |

1pc |

|

Complete tooling |

1set |

|

Certificate |

1pc |

|

Operation Manual |

1pc |

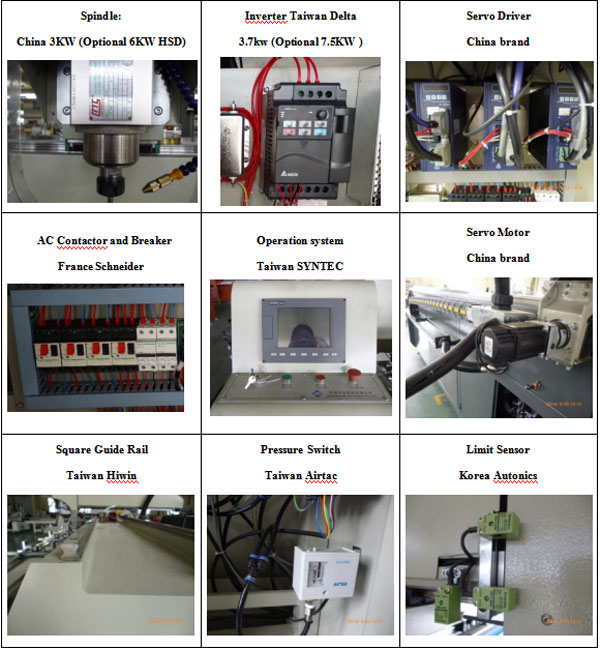

Machine details